What are the Different Types of Duplex Paper Board?

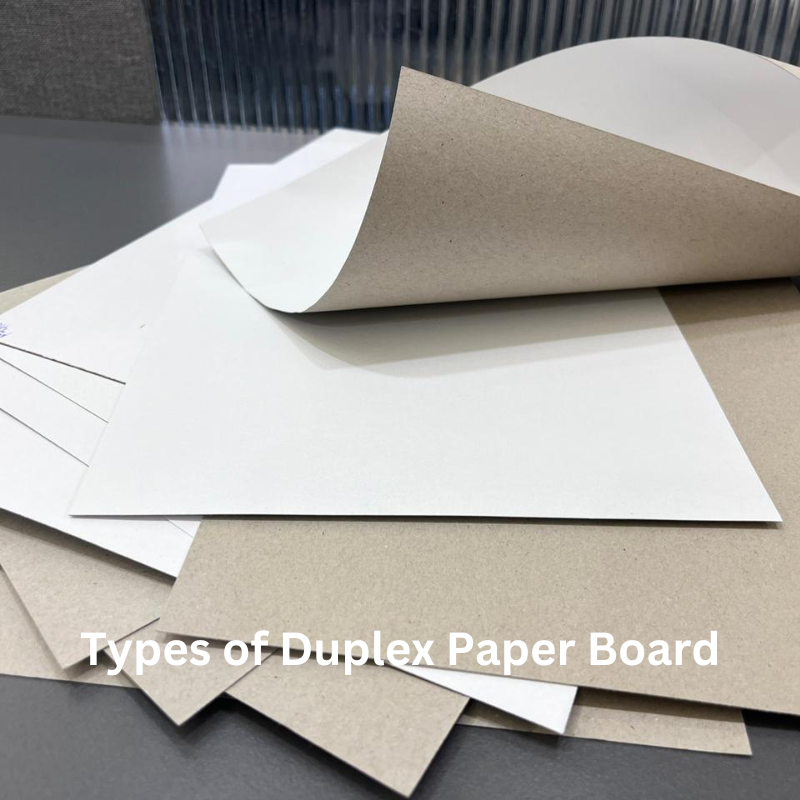

Duplex paper board is a type of paperboard or cardboard that is widely used for packaging, printing, and various other applications. It is known for its sturdiness, smooth surface, and ability to withstand wear and tear. Duplex paper board is available in various types, each with its own unique characteristics and suitability for different purposes. In this article, we will explore the different types of duplex paper board and their specific uses.

1. Coated Duplex Board

Coated duplex board is one of the most commonly used types of duplex paper board. It is coated with a thin layer of kaolin clay or other coating materials to enhance its smoothness and printing properties. This type of duplex board is ideal for packaging applications where high-quality printing is required, such as for food packaging, cosmetics packaging, and pharmaceutical packaging. The coating helps the board achieve vibrant colors and sharp images, making it perfect for products that require attractive and informative packaging.

2. Uncoated Duplex Board

Uncoated duplex board, as the name suggests, does not have any coating on its surface. It has a natural, rougher surface compared to coated duplex board, which makes it suitable for applications where printing quality is not a primary concern. Uncoated duplex board is commonly used for products that are packed in inner boxes within the outer packaging, as well as for applications where the surface will not be directly visible to consumers. It is also used for industrial packaging, book covers, and various general-purpose packaging needs.

3. White Back Duplex Board

White back duplex board is a type of duplex paper board that has a white, smooth surface on one side and a natural grey or brown surface on the other side. This type of duplex board is ideal for applications where one side needs to have a high-quality print finish while the other side remains hidden from view. It is commonly used for packaging of products where the interior of the packaging requires a clean and premium appearance, such as electronic gadgets, luxury items, and gift boxes.

4. Kraft Back Duplex Board

Kraft back duplex board, on the other hand, has a kraft paper backing on one side, providing a natural and organic appearance. This type of duplex board is often used for products that require an eco-friendly and rustic packaging look, such as organic foods, natural cosmetics, and eco-friendly products. The kraft backing also provides additional strength and tears resistance to the duplex board, making it suitable for heavy-duty packaging needs.

Duplex paper board offers a versatile and cost-effective packaging solution for a wide range of products. With various types available, each catering to specific needs and preferences, manufacturers and designers can choose the most suitable duplex board for their packaging requirements. Whether it is for high-quality printing, industrial packaging, or environmentally conscious products, duplex paper board continues to be a popular choice in the packaging industry.